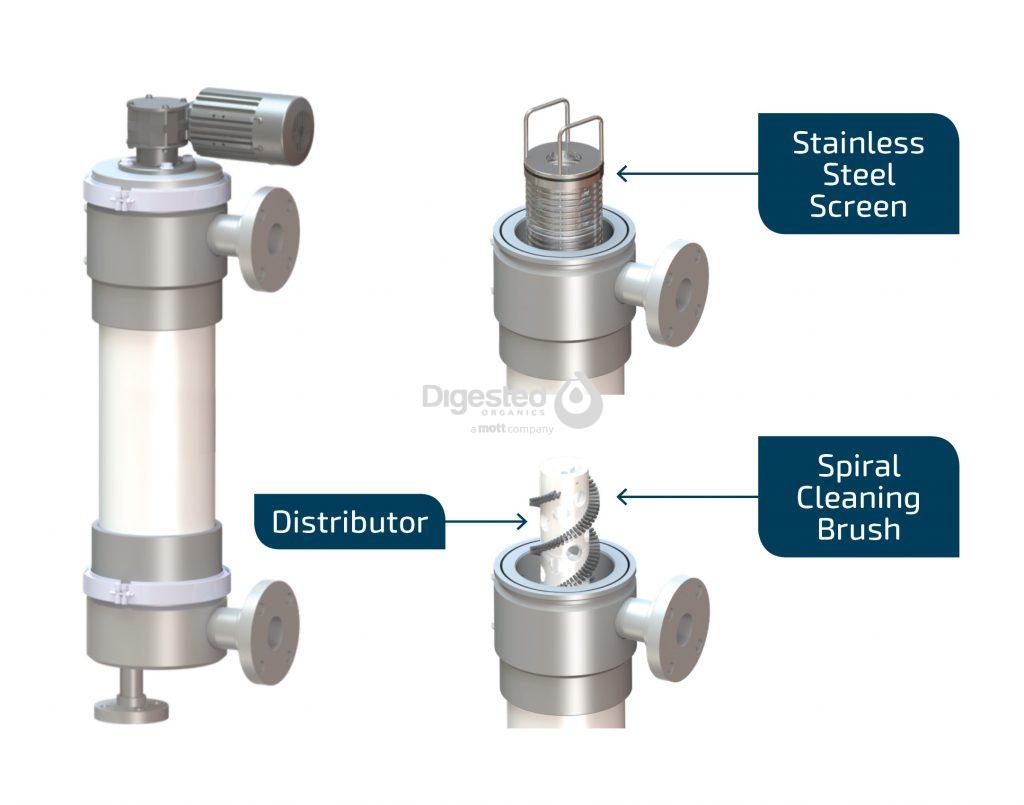

High-Throughput Continuous Screen Technology

The wastewater to be filtered flows into the top of the unit where it enters the interior of the cylindrical screen. Clarified material, or filtrate, exits the unit by passing through the screen while the solids accumulate inside the screen. The motor spins a spiral-shaped cleaning brush within the screen, keeping the screen clean and pushing the accumulated solids to the purge outlet at the bottom of the unit. An automated valve opens periodically to discharge these solids out of the unit—there is no disruption to the process flow and no shut down time for backwashing.

KEY FEATURES

Automatically Self-Cleaning

Handles High and Variable TSS (25,000+ mg/L)

Low Cost / Low Maintenance

Continuous Filtrate with up to 99%+ Recovery

Patented Technology

Single units or Multiplex

Versatile Applications for Wastewater Management

The Spiral Brush Screen Filter is exceptionally suited for a wide range of wastewater management needs, from the food and beverage industry to agricultural effluents in manures and lagoons, and even for irrigation systems. Its design efficiently handles high-load wastewater, offering a sustainable and effective solution for solids separation and improved water quality across diverse sectors.

How The Spiral Brush Screen Filter Works

In the Spiral Brush Screen Filter system, wastewater enters the screen from the top, separating solids inside the cylindrical screen as clean water passes through. A motor-driven spiral brush continuously cleans the screen, transporting solids to a purge outlet. This process allows for uninterrupted operation without the need for backwashing, ensuring efficient filtration and disposal of solids, aligning with the SEO keyword focus.

Multiplex Skids

The Spiral Brush Screen Filter’s versatility and efficiency are further enhanced by our customizable multiplex skids, designed to meet a range of operational needs and settings:

- Availability of 1 to 4 units per skid, with material options of powder-coated steel or stainless steel.

- Stainless steel screens ranging from 10 to 100 microns for tailored particle size removal and throughput.

- Features custom-engineered plastic brushes within the screens, supported by high-efficiency motors.

- Incorporates isolation valves for selective maintenance without disrupting service.

- Equipped with a water inlet valve for system flushing, a maintenance-friendly platform with non-slip grating, and NEMA 4X enclosures with HMI for simplified operations.

Equipment Options

Model 850

- Inlet: 2” FNPT or #150 Flange

- Filtrate Outlet: 2” FNPT or #150 Flange

- Purge Outlet: 2” FNPT or #150 Flange

- Max Flow: 100 gpm

- Screen Micron Rating: 15 – 100 micron (wedgewire type)

- Max Operating Pressure: 120 psi @70°F

- Max Temp: 190°F

- Head Loss: 1-3 psi)

- Brush Motor: 1 HP (460V, 3-Ph)

- Wetted Housing: CPVC, 2205SS, Acetal

- Seals: EPDM or Viton

- Cleaning Brush: Acetal, Nylon 6.12 & 316 SS

- Filter Element: 316L SS

Model 1000

- Inlet: 3” FNPT, Flange, or Tri-Clamp

- Filtrate Outlet: 3” FNPT, Flange, or Tri-Clamp

- Purge Outlet: 3” FNPT, Flange, or Tri-Clamp

- Max Flow: 250 gpm

- Screen Micron Rating: 15 – 100 micron (wedgewire type)

- Max Operating Pressure: 150 psi @70°F

- Max Temp: 190°

- Head Loss: 1-3 psi

- Brush Motor: 7.5 HP (460V, 3-Ph)

- Wetted Housing: 316 SS

- Seals: EPDM or Viton

- Cleaning Brush: Nylon 6.12, 316 SS, UHWM-PE

- Filter Element: 316L SS

APPLICATIONS

Wastewater clarification

Suspended solids removal

Food and beverage manufacturing wastewater

Flush manure clarification

Brewery wastewater clarification

Pre-filtration for existing UF or RO system or our own Forward Osmosis™

Enhancing Wastewater Management with the Spiral Brush Screen Filter

The Spiral Brush Screen Filter is a pivotal solution designed for effective wastewater treatment. This innovative system is engineered to remove solids from liquids, making it ideal for various industries, including food and beverage production and agricultural applications. Its unique spiral brush mechanism ensures continuous, efficient operation, reducing maintenance needs and enhancing overall filtration efficiency. This filter represents a step forward in sustainable wastewater management practices.

PLEASE CONTACT US TODAY TO LEARN ABOUT AVAILABLE PILOT TESTING IN-HOUSE AND RENTAL UNITS.

Reference Articles

Fresh From The Blog

FAQs: Spiral Brush Screen Filters

What is a Spiral Brush Screen Filter?

A Spiral Brush Screen Filter is an advanced filtration system designed to remove solids from wastewater efficiently, utilizing a spiral brush mechanism to maintain cleanliness and flow.

How does the Spiral Brush Screen Filter work?

It operates by directing wastewater through a cylindrical screen, where a motor-driven spiral brush continuously removes debris, allowing for uninterrupted filtration and disposal of solids.

What are the key benefits of using a Spiral Brush Screen Filter?

The key benefits include improved water quality, reduced maintenance due to its self-cleaning mechanism, and high efficiency in solids removal, making it ideal for various industrial applications.

Can the Spiral Brush Screen Filter be used in agricultural applications?

Yes, it is particularly effective in agricultural settings, including manure management and irrigation systems, due to its ability to handle high-load wastewater and enhance water recycling processes.