Leading Solutions for Industrial and Municipal Water Challenges

Digested Organics delivers cutting-edge solutions for both industrial wastewater producers and municipal wastewater treatment plants, aiming to lower disposal costs, enhance nutrient removal, and diminish chemical use.

Key Applications Include

Suspended solids removal prior to sewer discharge or biological treatment using our Spiral Brush Screen

Sludge dewatering from MBRs or activated sludge processes using our stainless steel Ultrafiltration System

Water reclamation from secondary or tertiary treated municipal wastewater using our Forward Osmosis process

Customized Filtration for Diverse Applications

Our diverse offerings cater to a wide range of applications, ensuring compliance and efficiency in wastewater management:

- Suspended Solids Removal: Utilize our Spiral Brush Screen for pre-discharge cleansing or prior to biological treatment.

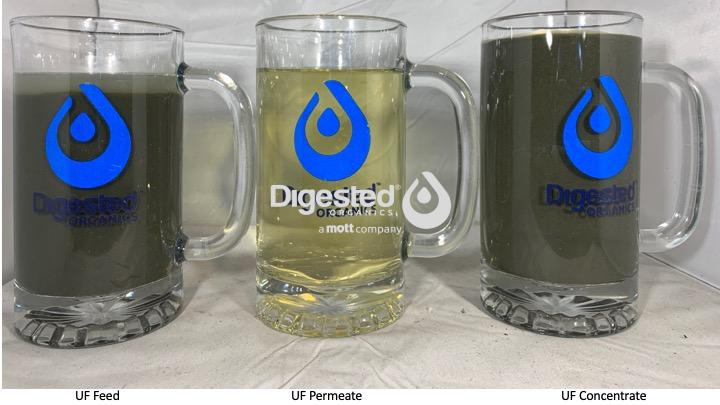

- Sludge Dewatering: Our Stainless Steel Ultrafiltration System excels in processing sludge from MBRs or activated sludge processes.

- Water Reclamation: Employ our Reverse Osmosis process for reclaiming water from treated municipal wastewater, promoting sustainability and cost savings.

Advantages of Our Approach

- Automation and Ease of Use: Our systems are highly automated, requiring minimal operator intervention.

- Chemical-Free Processing: Simplify operations while enhancing the value of concentrates through our chemical-free processing.

- Water Reuse: Enable the reuse of water for various purposes, contributing to environmental sustainability and operational efficiency.

Innovative Approaches to Water Reclamation and Sludge Management

- Spiral Brush Filter: A versatile tool for TSS and BOD reduction before biological or advanced filtration.

- Stainless Steel Ultrafiltration: Ideal for dewatering or thickening sludge, concentrating wastewaters efficiently.

- Forward Osmosis: A revolutionary method for reclaiming water from industrial effluents, reducing freshwater consumption and enabling beneficial reuse.

Achieving Excellence in Wastewater Management

Selecting Digested Organics propels industrial and municipal operations towards unparalleled wastewater management excellence. This choice signifies a commitment to environmental sustainability and operational optimization. Our solutions bridge the gap between ecological responsibilities and the need for operational efficiency, offering a pathway to not only meet but exceed regulatory standards. Through our partnership, entities gain access to innovative technologies and expert guidance, ensuring wastewater management practices that are not just compliant, but are also a testament to environmental stewardship and operational savvy.

Reference Articles

Fresh From the Blog

FAQs: Industrial Wastewater Treatment

What is industrial wastewater treatment?

It’s the process of treating water that has been contaminated by industrial or commercial activities before it is released back into the environment or reused within the facility.

Why is treating industrial wastewater important?

Effective treatment removes harmful pollutants, ensures regulatory compliance, protects public health and the environment, and conserves water resources.

How does Digested Organics address industrial wastewater challenges?

Through advanced filtration and treatment technologies that reduce contaminants, recover valuable resources, and enable water reuse, enhancing sustainability and operational efficiency.

Can Digested Organics' systems be customized for different industries?

Yes, our solutions are designed to meet the specific needs of various industrial sectors, ensuring optimal performance and compliance with environmental standards.